FlexSteam Control System For Enhanced Oil Recovery Steam Generators (OTSG)

Introducing the FlexSteam Control System

Accurately predict your steam discharge quality with the FlexSteam Control System.

Whether your generator is 5 or 50 years old, whether you’re outputting 5,000 or 100,000 pounds of steam per hour, we’ve designed a steam generator control system that automates the entire process and enables you to predict your steam discharge quality within very fine tolerances.

Standardized yet Adaptable

With FlexSteam we’ve standardized our control system software to fit any sized generator — and yet there’s plenty of room for customization: Choose to burn natural gas, propane, oil or diesel fuel. Specify your generator size and other variables such as water flow and steam pressure. The FlexSteam Control System offers the quick installation and simple setup you need, while still giving you all the options you want.

Complete Automation

Cenovus_2

Return On Investment (ROI)

It’s not uncommon for our customers to see a 20% increase in fuel-to-steam efficiency after installing FlexSteam. Thanks to higher steam quality, lower fuel costs, emissions control, automation, and ease of use, FlexSteam can pay for itself in as little as a year or two.

AREAS OF EXPERTISE

Control system engineering

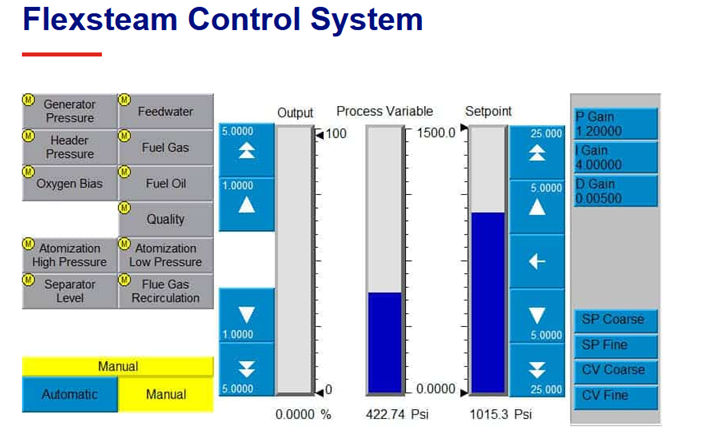

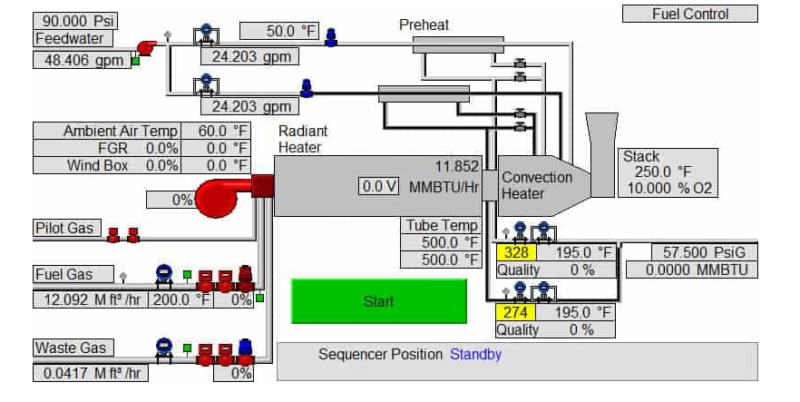

Remote system monitoring Flexsteam Control System

Provides an overview of oil, water, pressure, levels and other main processes.

FlexSteam provides a comprehensive control system that allows the operator to set their own parameters, perform basic troubleshooting and bring their generator within much tighter tolerances.

FlexSteam Control System includes:

• Control panel

• PLC

• Operating system with tablet

Adjust feedwater, ambient air temp, pilot gas, fuel gas, waste gas and more — without a call to the manufacturer.

From a single touchscreen specify these essential parameters:

• Pounds of steam per hour • Accurately predict steam discharge quality

• Fuel type • Track and control emissions

• Water flow • Perform complete adjustments

• Steam pressure • Engineering changes

• High and low limits and alarms • Operational revisions

Most manufacturers require you to call them for this type of service, leaving you to wait for a technician’s arrival.

FlexSteam Control System includes an onboard knowledge base, updated with feedback from customers like you. Our FlexSteam control panel, PLC and operating system provides this power at your fingertips.

Change your steam per hour from 900 to 30,000 pounds?

Burn diesel instead of propane?

Call us! We customize to your specifications. 316.776.7500 EXT. 125

| City | Rose Hill |

| State/Province | KS |

| Country | United States |

| Zip/Postal Code | 67133 |

| Quantity | 10 |

| Demo Page URL | https://theacesinc.com/products/steam-generators/ |

| I Want To | Sell |

| Telephone Number | 3167767500 EXT. 125 |

| Email Address | darren.moore@theacesinc.com |

NotesThis System is in use Worldwide. |