EcoSyn®-174 Synthetic Acid

$Call for Info

EcoSyn®-174 Synthetic Acid

Synthetic Acid Technology

• What is it?

• EcoSyn®-174 is a manmade product which has the properties of HCL without the extreme corrosiveness.

• The product falls between how a high strength mineral acid and a low strength organic acid works. It is slower acting than HCL but will dissolve more CaCO3 per volume.

• Is it “Green”?

• EPA – DfE, FDA GRAS Approved

• Regulated as Non-Hazardous(Non-Toxic, Non-Corrosive, Non-Fuming)

• Environmentally Friendly

• 10 day, 100% biodegradability

• Non destructive to skin

• Non destructive to eyes

Components

– Syntech® Acid

– Non-ionic surfactant/de-emulsifier

– Iron control agent

– High temp corrosion inhibitor

– Compatible with gelling agents (Cationic PA, HEC, Low Ph Polymers)

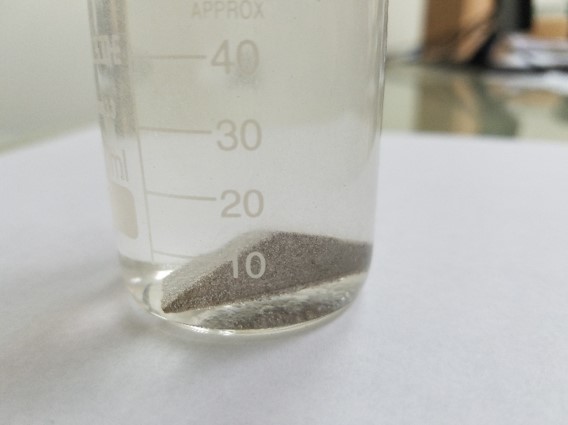

Spend Rate and Dissolution

• EcoSyn®-174 has a more linear and controlled spend rate which results in less near wellbore damage during squeezes. Can also be delivered with our acid fogging delivery system for ultra-deep reservoir placement.

• EcoSyn®-174 at full strength(30%) will dissolve approximately

2.2lbs/gal of CaCO3. *

• At a 15% concentration, EcoSyn®-174 will dissolve 10.7% more CaCO3

than a 15% HCL.*

Precautions

• EcoSyn®-174 is a low Ph product which will react with certain soft metals like magnesium and aluminum. Care should be taken to ensure that only approved hoses, Camlok fittings and equipment are used when loading and unloading.

• EcoSyn®-174 can be stored in approved plastic/fiberglass containers,fiberglass lined acid tanks and lined steel tanks (short term).

EcoSyn®-174 Advantages over HCL

• Lower friction pressures requiring less HP

• Slower spend rates, linear vs hockey stick

• Completely mixes with water in any concentration

• Product will not separate in storage tanks

• Can be used with basic equipment

• No off gassing

• Triple 0 environmental rating

• Order of magnitude lower metal corrosion rate. May eliminate corrosive surcharge on wireline and coiled tubing.

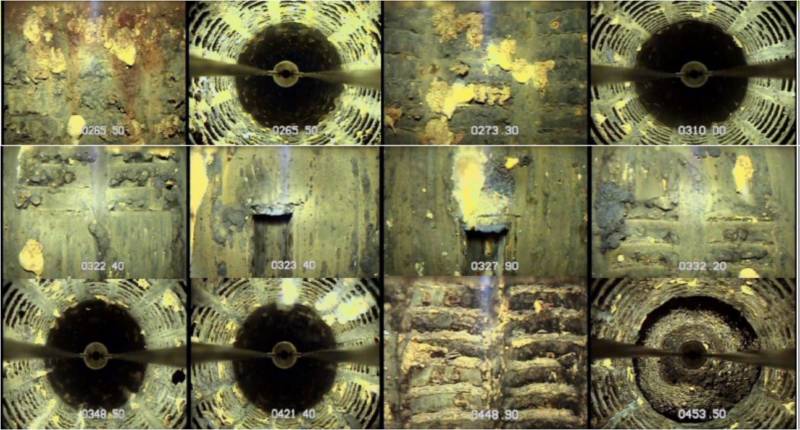

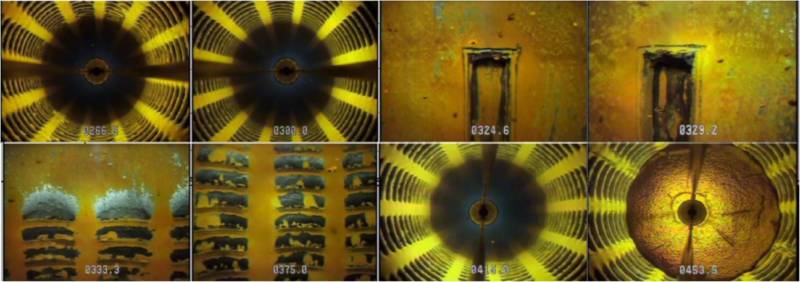

Brine Disposal Well, Venango County PA

• Application: 275 gallons of EcoSyn®-174 was pumped into tubing then immediately followed with brine.

• Results: Over a 2 day period, injection pressures dropped from 1000psi to 260psi. Injection rate increased by over 30%. Over following 3 week period, the injection pressure cycled between 300 and 600psi then settled in around 600psi with no loss of injectivity.

• Downtime: Unlike with HCL treatments, there was no downtime due to off-gassing or 3rd party pumping. The brine injection rate immediately increased and has remained constant for a month.

• Other Observations: When brine filters were exposed to EcoSyn®-174, all traces of iron oxide were removed and the material stayed in solution. The injection rate and pressure has been significantly more stable than when well was treated with 20% HCL.

Other Benefits of our product over HCL:

Ecosyn 174 is a manmade product that falls in between an HCL and something like an Acetic acid. In the manufacturing process they actually start with HLC and then change it’s chemical makeup. The resulting product won’t burn your skin or corrode steel like HCL but it will have the same dissolution results. It’s biggest benefit is it’s longer spend rate. On long horizontal wells, HCL will spend before it even hits the toe of the well. This product spends over a couple of hours.

EcoSyn-174 will reach about 60% of it’s spend in about 30 minutes compared to 6 minutes for HCL. In lab testing I’ve seen indications of a continued reaction after over 90 minutes

| State/Province | Texas |

| Country | United States |

| Quantity | 100000 |

| Allow Deals | Yes |

| I Want To | Sell |

| Telephone Number | 7402970289 |

Notes1. First Picture Shows screen Pre Treatment |