Coalescing Oil and Water Separators For Sale

$Request Quote

Coalescing Oil and Water Separators For Sale

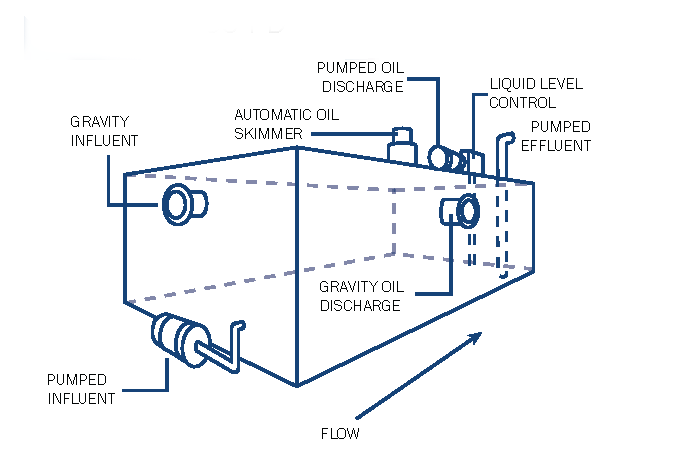

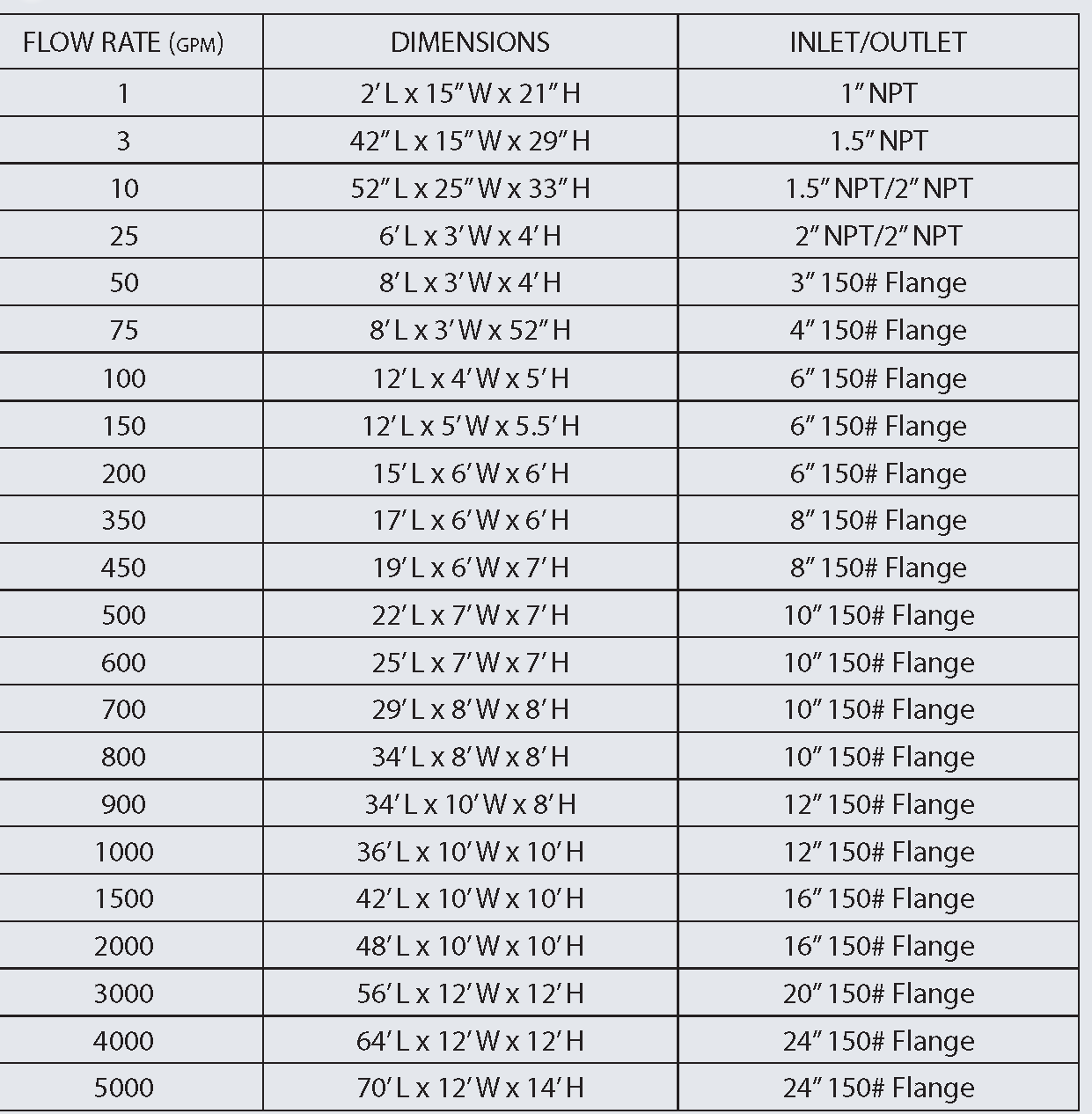

Pressurized coalescing oil/water separators,from 1-5000 gpm for a wide variety of industrial applications. These CS Series separators effectively reduce free oil and grease content in waste streams to 10 mg/ or less through the use of high efficiency PVC and CPVC corrugated plate modules providing high quality,consistent effluent results.

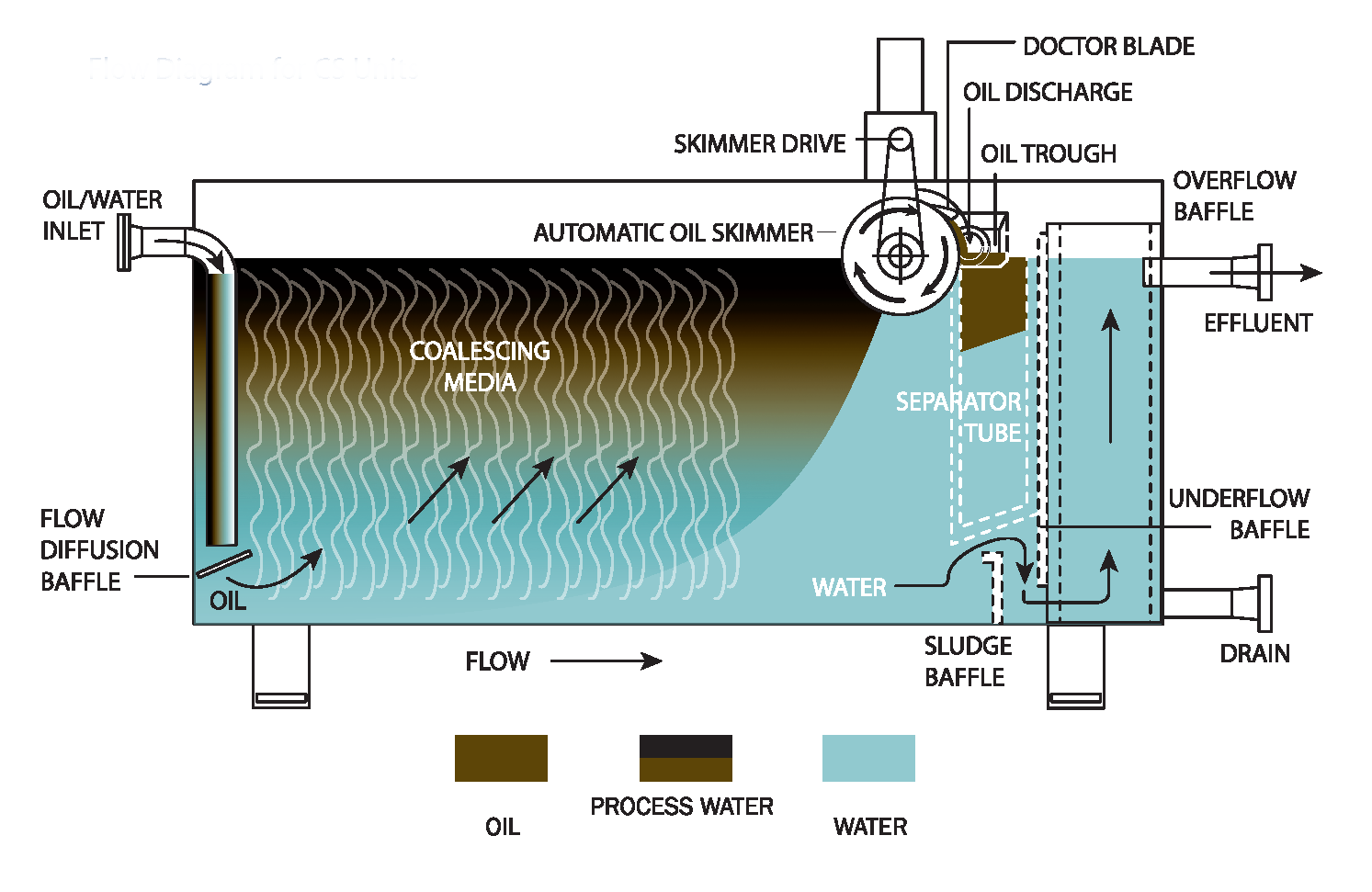

Oil and water in fluent is induced through the standpipe to the tank interior. The influentis evenly distributed by the flow diffusion baffle before entering the coalescing module. The module, being oleophilic,begins to attract the oil droplets which in turn begin to bod or coalesce into larger droplets. These large droplets continue to rise where they form a layer of oil on the surface.

The separator employs a continuous acting rotary pipe oil skimmer to remove the oil from the surface and deposit it into the oil separation tube. The majority of the water which may have been removed with the skimmed oil separates back out into the waste stream. The separated oil then discharges out of the separator.

The water continues through a series of underflow and overflow baffles before discharging from the unit.

COALESCING MEDIA

TPS Series oil/water separators utilize a unique coalescing media which provides for a high quality, consistent separation process. This configuration will also reduce internal sludge and solids buildup due to its steep vertical flutes.

Standard material

is PVC rated to 140° F and polypropylene

to 200°F continuous. Stainless steel media can be supplied for temperatures that exceed 200 °F.

The media can be removed through the manways for simplified cleaning.

UNIQUE DESIGN ADVANTAGES

• Effective free oil removal to 10 mg/l or less @ 20 micron

• No costly cartridges or filter elements to replace.

• Coalescing media requires only periodic cleaning

• Fully automatic operation

• High efficiency coalescing module

• Operating temperature to 205°F

• Operating pressures to 600 psi

• Flow diffusion baffle for even flow distribution at the inlet channel

• Constructed for Durability

• High-performance phenolic epoxy interior coating for maximum protection

• Heavy mild steel construction:

| State/Province | Ohio |

| Country | United States |

| Quantity | 10 |

| Allow Deals | Yes |

| I Want To | Sell |

| Email Address | info@oilpatchsurplus.com |