New – Trailer Mounted 60” OD x 15’-0” S/S Horizontal Four Phase Separator

New – Trailer Mounted 60” OD x 15’-0” S/S Horizontal Four Phase Separator

Located in Texas, ready for delivery. Call 403-620-7086

Design Conditions:

Design Pressure: 1440 psig

Design Temperature: -20° F / 130°F

Shell Diameter: 60” O.D

Shell Length: 15’-0” S/S

Shell Thickness: 2.25” Nom

Shell Material: SA-516-70N

Type Head: 2: 1 Semi-Ellip

Head Material: SA-516-70N

Head Thickness: 2.25” Nom.

X-Ray: RT-1

PWHT: Yes

U.T.: Not included

ASME Code Stamp: Section VIII, Div. I

National Board Registered: Yes

Pipe: SA-106B/C

Flanges: SA-105/SA350 LF2

Connections:

One (1) Inlet Connection 8” 600# RFLWN Flange

One (1) Outlet Connection 6” 600# RFLWN Flange

One (1) Manway 20” 600# RFLWN

One (1) Water Level Controller Connection 2” 600# RFLWN

One (1) Oil Level Controller Connection 2” 600# RFLWN

One (1) Water Outlet Connection 3” 600# RFLWN

One (1) Oil Outlet Connection 3” 600# RFLWN

One (1) Water Drain Connection 3” 600# RFLWN

Two (2) Solids Drain Connection 3” 600# RFLWN

Four (4) Level Gauge Connections 2” 600# RFLWN

Teo (2) PSV Connection 2” 600# RFLWN

Internals:

One (1) Non removable Stainless Steel mist Vane

One (1) Inlet Diverter

Two (2) Vortex Breaker

One (1) Spill Over Plate

One (1) Solids Weir Plate

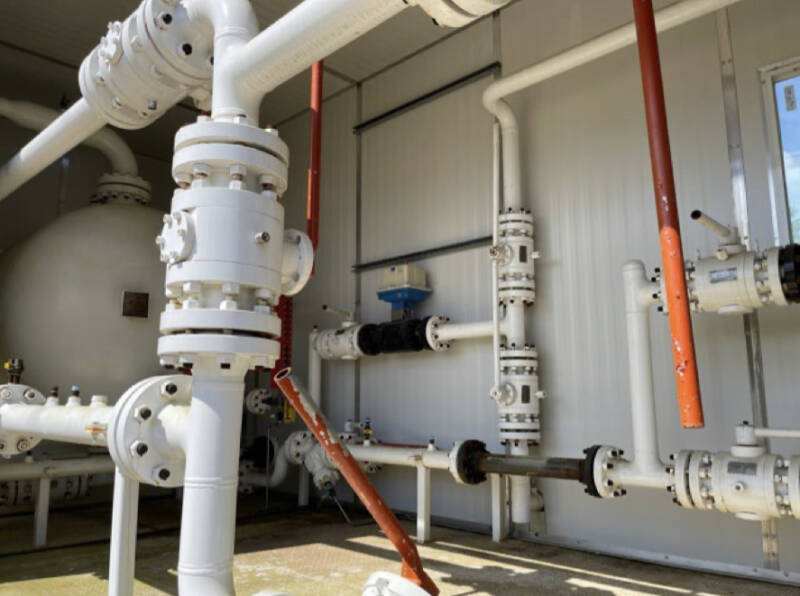

Piping:

All to be ANSI 600RF. Only instrument air piping to be NPT

Inlet – 3’’inlet to 8’’into the vessel

Gas outlet – 6” outlet to 4” meter line with gas measurement, 3” pressure controller and 3”

Outlet:

Water and oil outlet – 3” outlet with (1) 3” turbine meter and (1) 2” turbine meter protected by

y-strainers with level control valves and check valves, 3’’bypass for control valves

Drains – (2) 3” lines w/ isolation valves

PSV’s – (2) 2” x 3”, able to vent to atmosphere or to flare

(1) co-mingle line, co-mingling oil, water, and gas

Valves and controls

20 – 3” ANSI 600RF Morris Floating ball valves

4 – 2” ANSI 600RF Morris Floating ball valves

26- ½” NPT SS 2000 PSI ball valves

13 – 1” NPT SS 2000 PSI ball valves

3- ¼’’ 67CFR regulators 0-60psi, 250psi max inlet

2- 1’’ little Joe regulators 70-120psi 1500psi max inlet

1– instrument air gas scrubber 250psi MAWP ASME coded

1-fuel gas shut-off

1-1/2’’ ss liquid filled 300psi gauge

1-1/2’’ ss liquid filled 1500psi gauge

2-0-250 thermometers w/ thermowells

2 – 3” ANSI 600RF x 4” ANSI 150 snap pilot operated PSV’s – Mercer

2 – 3’’600#RF Fisher L2 level controllers with vertical displacer

2– 3” ANSI 600RF CVS pressure to open control valves, SS full open trim 1– 3” ANSI 600RF CVS pressure to close control valves, SS full open trim 1 – Transparent level gauge

1 – Reflex level gauge

1 – Barton chart recorder with 5 valve manifold

2 – 3” x 2” Kimray liquid turbine meters with XP B3000 monitors

1 – 2” x 1” Kimray liquid turbine meters with XP B3000 monitors

1 – 4” 600RF senior Daniels 14.3 orifice meter w/ flange flow conditioner

1-Barton Chart w/ 5 valve manifold

Paint:

External

One (1) Blasted

One (1) Coat Shop Primer

One (1) Topcoat Shop Standard

Trailer

53’ Wade 120,000# Drop Deck Tri-Axel

Non-destructive Testing:

Welding with ASME Section IX weld procedures and NDE per ASME Section V., Separator testing will consist of 100% Radiograph of Long Seams and Spot Radiograph of Girth Seam welds