(2) 30ft X 106ft 2,000 Ton Industrial Storage Tanks For Sale New Never Installed

$1,350,000

(2) 30ft X 106ft 2,000 Ton Industrial Storage Tanks For Sale New Never Installed

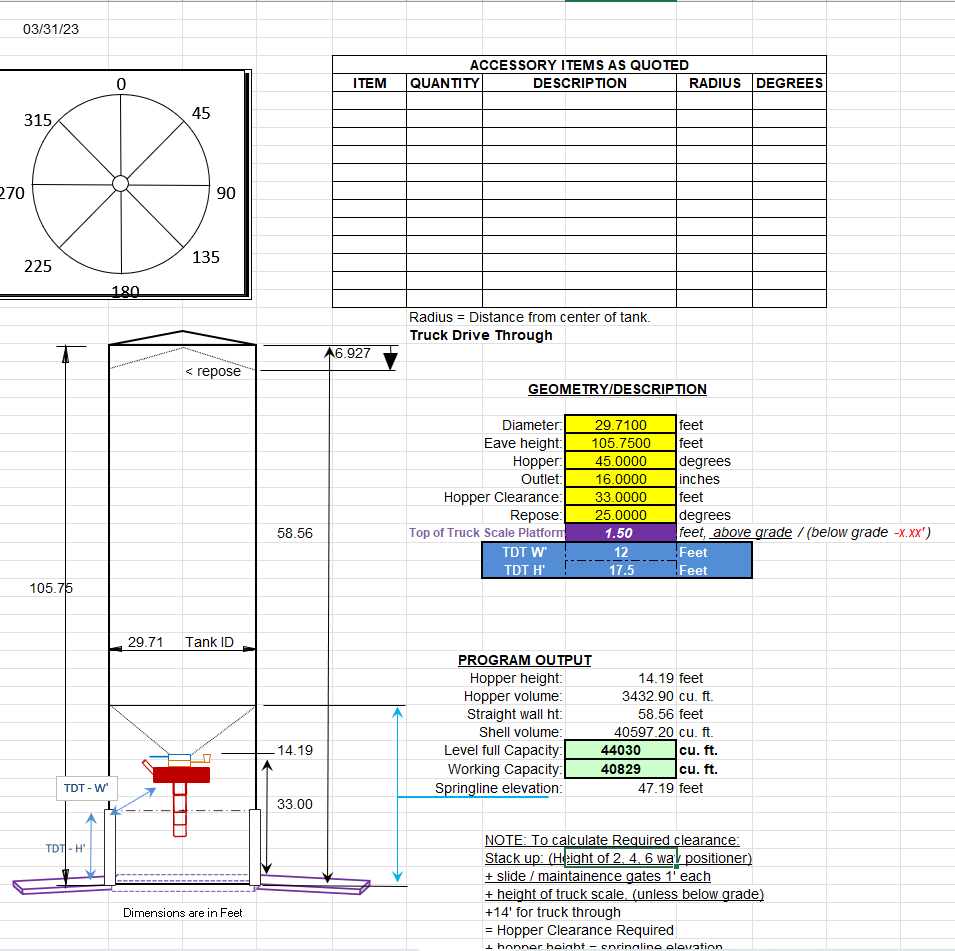

1) G eo m et r y/Desc ri p t io n

Bolted carbon steel rolled, tapered panel “RTP” industrial storage tank

29.71’ Nominal inside diameter

105.75’ Nominal eave height

58.41 Approx. straight wall storage height

Tanks will have:

45 Degree hopper slope terminating with a 16” diameter flanged outlet

Full skirt support with openings (12’ wide x 17.5’ high) for truck drive-through. Hopper outlet is

elevated to provide 33.00’ clearance from base of skirt support.

1:12 Deck slope

Level full capacity of 43,860 cubic feet

Estimated working capacity of 40,660 cubic feet based on 15 degree angle of repose- 2033 tons

2) Design Cri t er i a

Seismic zone per IBC 2012 – Site Class D, I = 1 (Ss=11.86% ; S1=5.83%)

90 MPH wind conditions per IBC – Exp. C, I = 1

Loads imposed by funnel flow pattern

Design pressure & vacuum is 2.0 oz. positive, 1/2 oz. negative

Center fill/center discharge

20 PSF Deck live load

Storage of free flowing Frac Sand or Equivalent Approved Alternative:

NTE: Product weight of 100 PCF volume, 100 PCF for design

Ambient operating temperature

3) Co at i n gs

Interior:

Interior skirt:

Exterior:

FUSION 5500 FBE™ @ 5-9 mils DFT

FUSION 5500 FBE™ @ 5-9 mils DFT

FUSION 5500 FBE™ + EXT FUSION SDP™ @ 6-10 mils DFT

Customer to specify from TC std. C olors:

TC-White, TC-Tan, Light Gray, TC-Light Green, and TC-Light Blue

See note #7 below for more information regarding premium and custom colors.

Notes: 1. All coatings are baked-on formulation, applied over an SP10 surface preparation

2. Touch-up coating kits for interior and exterior are provided for field application.

3. Fusion 5500 FBE – A proprietary system unmatched in performance compared to ALL

bolted tank linings.

Note color is Gray (no choice of color is available for primer).

4. Fusion 5500 FBE & EXT Fusion SDP – A proprietary exterior system that profiles

as “powder fused on powder” system

5. DFT = dry film thickness

6. FBE = fusion bonded epoxy powder coating, SDP = super durable polyester powder coating

4) Co mp o n e n t s/Accesso ries Each of (2) Tanks

TC tank logo

Touch-up coating for interior/exterior

Anchor bolts & nuts Anchor bolt template

EPDM Gasket

Grade 8 Hardware

2 – 12’ Wide x 17.5’ Tall openings in skirt at grade for truck drive through

1 – 3’ x 6’8” White HEAVY-DUTY industrial walk-in door in skirt at approx. 15’elevation for access

to customer provided interior platform

1 – 36” Diameter center roof dome with cover plate – 5,000# max deck load from chute

1 – 24” Diameter combination manway pressure/vacuum relief valve (2 oz. pressure, 0.5 oz. vacuum)

1 – 20” Dia. hopper bolt-on manway access

2 – Flanges on deck for level indication – designed for 250# max. dead load

1 – 43” Sq. flange for bin vent filter – 850# max. load (Wind bracing members are not

included)

2 – Exterior support columns at eave (12” projection above eave) 15K vertical,

20K horizontal (radial or tangential) per column

2 Only – Set of Bucket elevator supports, with loads as follows at each support:

Elevation 4.75’= #2,553

Elevation 24.75’= 4,674#

Elevation 44.75’= 5,052#

Elevation 64.75’= 5,347#

Elevation 84.75’= 5,590#

Elevation 104.75’= 14,000#

(Customer to supply and/or verify loads prior to final design and pricing)

Deck perimeter guardrail – OSHA – HDG (TC std. construction)

Bolted Winding stairway from grade to eave, 30” wide with one (1)

top step off platform at eave.30 in wide with one top step off at eave and one 48 by 96 platform at 15 ft

elevation for access to the interior platform provided by others.

Stair utilizes blistered panel industrial stair treads with interior and exterior rails – HDG – OSHA (TC std.

construction)

1 Only Bolted crossover for 8 ft span between tanks – HDG-OSHA ( TC stnd construction)

2 – Full interior galvanized steel support platforms for access to loading equipment

(2) BIN VENT DUST FILTERS, Model 72AVS16 STYLE III with SB12 Exhaust Fan

COMPLETE WITH:

• 145.6 Sq. ft. of media with an air to media ratio of 5.6:1 @ 800 CFM

• Filter stressed for 17″ WC(1.25″Hg) vacuum

• Carbon steel construction, all product contact parts

• Carbon steel clean air plenum

• Exterior welds continuous where possible and cleaned free of weld slag and splatter

• Product contact welds are non-continuous(skip welds), with no grinding, other than to be free of weld slag

and splatter

• 18″ x 38″ Hinged T-handle style housing access door

• 3/4″ Diaphragm Valves with 4″ diameter compressed gas header

• NCC Timer and Goyen solenoid valves mounted and prewired in a NEMA 4 enclosure

• Timer and enclosure voltage, 120VAC/1/60Hz

• Timer enclosure airlines to diaphragm valves, Polyflo tubing

• Mineral reinforced nylon bag cup and venturi

• 7″ O.D. exhaust